Airfield survey specialists trial systems at Glasgow Airport

“There's always a better way to do things; you just have to have an open mind,” says Paul Froes of technology SME SatSense, reflecting on a recent trial of automated pavement monitoring and inspection techniques at Glasgow Airport.

“Technology is constantly changing, so new approaches have to be tried; and this is where innovation comes in. Just because something has been done a certain way for many years doesn't mean you should always do it that way.”

Paul’s firm was one of four taking part in a Connected Airport Living Lab demonstration over three days in June, delivered by Connected Places Catapult in partnership with AGS Airports, to present new ways to deliver speedy and effective infrastructure maintenance airside.

Another trial participant was John Hill of Atlas Geoinformatics.

“The only way you learn is by doing things for real, so these programmes are fantastic. They smooth the way and let you try untested technology, so you can decide if a commercial proposition is worth developing.”John Hill of Atlas Geoinformatics

John adds that small companies trying to sell technology into a regulated space like aviation can face a bias towards incumbent suppliers. But the Catapult has helped, he adds, to “connect us to the right people, and talk about new ways of doing things.”

Elijah Hoole of Roadgauge – a third SME on the trial – said the Connected Airport Living Lab represented the first time his company had got to work in an airport environment, rather than roads, to detect surface defects. Without the programme, he adds, “it would have been very difficult to get a footing at Glasgow, start trialling so early and to be able to talk about our product.”

A fourth participant, Martyn Stonecliffe-Jones of software supplier Xais-Pts, says that innovating can be a slow process in the aviation sector due to regulations. But he adds that some airports still prefer to carry out manual inspections and walk the airfield looking for defects, rather than use modern methods of assessment.

“Airports need innovation, but there is also a need for airport owners to embrace innovation,” he says.

Surveys from the ground and sky

Three of the four trials at Glasgow Airport involved taking vehicles airside, with a fourth surveying the scene from the sky.

Atlas Geoinformatics used a vehicle-mounted sensor platform to accommodate kit including a laser scanner and cameras, and developed software that creates 3D models of an airfield. From this model, measurements can be carried out to identify defects, which could be used to predict the rate of degradation of a surface.

“We learnt from the Glasgow surveys that there are lots of different surfaces across an airport,” says John. “Each is constructed in a different way and has their own challenges and types of defect.”

Xais-Pts has developed a crack measurement system using lasers that can generate 56,000 scans every second, and provide results to an accuracy of 0.1mm. A 3D representation is created, and software identifies distresses to help populate a pavement condition index.

Martyn says surface conditions can vary significantly between airports, and that being proactive about monitoring can reduce large bills.

“It can cost several million pounds to resurface a runway. I’m surprised at the lack of detail that some airport owners have as to what their pavements are doing.”

Roadgauge creates 3D measurements of surfaces by using compact Go-Pro cameras, typically used by sports enthusiasts to record footage of themselves cycling or running.

“Data that we generate from the video recorded can produce actionable insights and measurements of cracks of only a few millimetres in depth,” says Elijah.

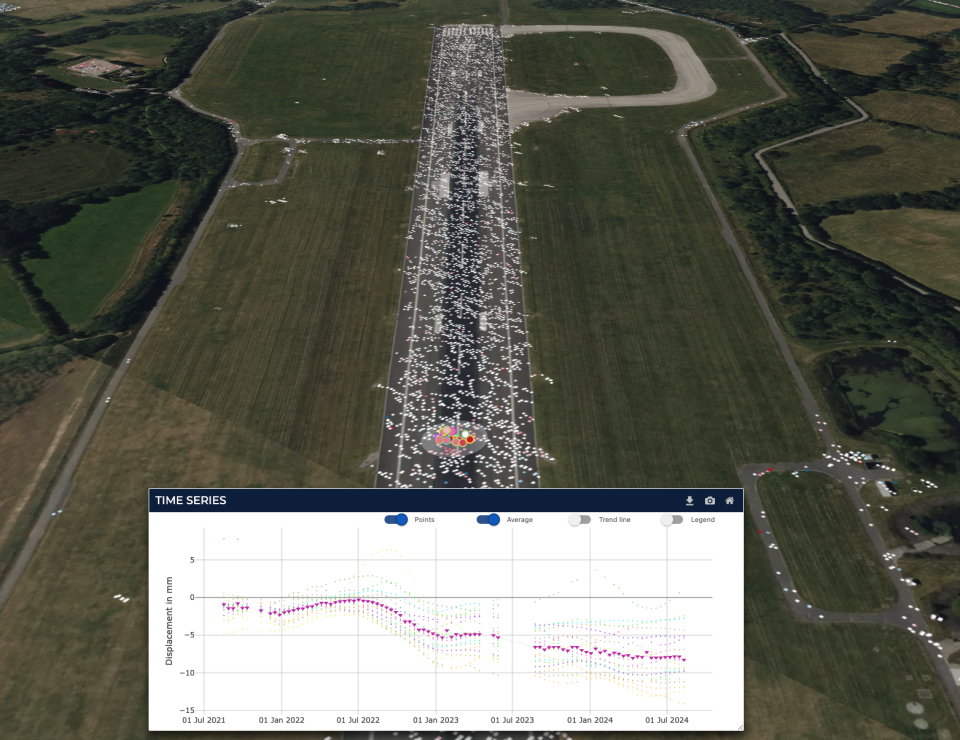

SatSense uses satellites to measure ground movement from the sky. Its system – more commonly used to monitor railways, roads, bridges, tunnels and buildings – can detect movement to within a few millimetres.

“We can start to identify ground movement risks before they manifest as structural failure affecting the runway, aprons or taxiways; as well as buildings beyond the boundary fence,” says Paul.

Catapult helps the conversation

Paul adds that getting technology into aviation can be hard, but Connected Places Catapult helped them to “get in there and talk to the right people. The natural progression is to form part of the ‘business as usual’ in providing smarter, predictive maintenance. The technology is there; it’s about applying it to new industries and use cases.”

John from Atlas Geoinformatics adds: “We've got to sweat the infrastructure harder, not just in airports, but all across the infrastructure space. The way you're going to do that is by using smarter technology to offer predictive maintenance.

“We are developing both our hardware and software off the back of the Glasgow trial, and hope to come back and collect some more data to show what progress we have made.”

Connected Places Catapult's Head of Aviation, Michael Laski says: “The automated pavement monitoring trials at Glasgow this summer have been a great opportunity to bring together a range of differing and complementary technologies that have previously been developed outside of aviation, and to test them within a live airport environment.

“We look forward to seeing the results of these different approaches to better understand their relative merits for potential use in a range of UK airport scenarios in the future.”

Read about further progress with the Connected Airport Living Lab: Entopy developing a digital twin at Glasgow, and accessibility trials for deaf passengers.