Clean Futures participant wins global award with rail infrastructure innovation

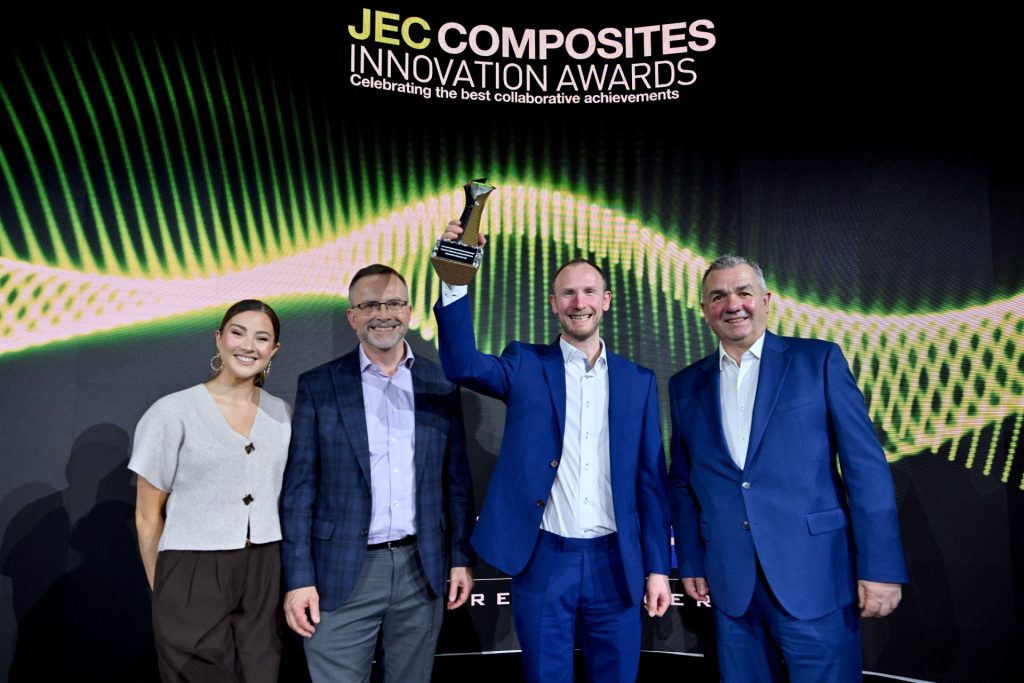

Composite Braiding – an alumnus of two rounds of the Clean Futures Accelerator programme – received an innovation award in France on Monday from what some have dubbed “the Oscars of the composites world”.

The Midlands-based manufacturer won the ‘Railway Vehicles & Infrastructure’ category at the JEC World 2026 Innovation Awards, for developing a lightweight composite twin-track cantilever structure to carry overhead power lines for trains.

Connected Places Catapult and Amey were recognised alongside the firm as the technology was developed during the second year of the Clean Futures programme, which was delivered by Connected Places Catapult and through which Amey partnered with the firm.

“Receiving a global composites award is really important to us because it signals to our peer group that we have made a major step forward in terms of our technology and its application,” said Composite Braiding’s Managing Director, Steve Barbour. “It's also a good recognition of the efforts of the team and the people we work with, including Connected Places Catapult and Amey.

“Several of the other winners on the night were major corporations, so we are punching well above our weight. Winning an award is something very special.”Steve Barbour, Managing Director, Composite Braiding

Use of braided composite material – in this case a glass-fibre reinforced thermoplastic – helps to reduce the weight of each cantilevered rail structure by 83% compared to steel, making installation easier. Carbon emissions associated with its construction are said to be up to 90% lower.

“We have ended up with something which is a lot lighter, more easily installed, and easier to be moved to where it needs to be. It is also electrically non-conductive, which is an important factor when working around two 25,000 volt power lines hanging from it.”

Each composite cantilever structure stands 8m high and 4.5m wide, and the company’s first installation was made possible through the Clean Futures programme at a rail test track in Dudley in the West Midlands. The company is now exploring several commercial opportunities with tier one suppliers in the UK, including Amey who it partnered with on Clean Futures with Connected Places Catapult.

Taking part twice in Clean Futures

Composite Braiding took part in the Clean Futures Accelerator twice: first in 2023 to develop a composite component for automotive use, and the following year to develop the overhead line equipment for rail in an effort to reduce the use of steel and concrete in transport infrastructure.

“We previously had interest from the rail sector for our composite technology and there was a lot of enthusiasm, but not a lot of forward movement,” says Steve. “The Clean Futures programme allowed us to progress in that sector, and use it as a catalyst for growth – which is now starting to bear fruit.”

He now hopes that the award win will get the company and its product noticed by international clients. “It provides a good level of credibility when we're going after new clients because what we do is novel, is different and not the norm.

“There's a certain amount of trepidation on the part of potential users of new equipment because they don't know the technology and there isn’t decades’ worth of data behind it. To have recognition in this form really helps stakeholders to look at what we do very seriously.”

Steve adds that the company decided to develop a composite rail structure that was of greatest use first – one that carries overhead power lines – rather than a simpler signal mast or Wi-Fi mast.

“Amey told us the two track cantilever was the most highly-loaded structure they had to work with on the Trans Pennine upgrade. It made sense to start with the most technically difficult product. A structure that stands 8m tall and is 4.5m wide is also difficult to ignore, so it is a statement piece. Composites have multiple applications in rail; there's a huge market for this.”

Helping the business to scale

Steve says the positive experience of taking part in the first Clean Futures programme gave the company the confidence to recruit four more staff, taking the headcount to 10. If commercial prospects are realised, he may look to double the staff number to 20 to meet demand.

“Clean Futures delivered for us; not just on the technical side, but in helping to grow the business. When we heard that the second cohort covered rail infrastructure, we went for it as that was part of our ambition. Our pipeline has developed significantly, and we are very close to closing some big deals that will further drive growth.

“Clean Futures was a catalyst for the business, and undoubtedly helped to increase the credibility of the technology and interest in our products.”

“Our aim is to deliver something that helps with rail electrification, is cheaper and more sustainable to install, creating benefit for the taxpayer and UK jobs.”

Find out more about the Clean Futures Accelerator and read a previous piece about the work of Composite Braiding.

Clean Futures is delivered by Connected Places Catapult alongside Coventry University. It is part of the wider West Midlands Innovation Accelerator, designed to bolster the region’s innovation and research and development capability, as well as its capacity to spark commercial growth and investment. The West Midlands Innovation Accelerator is delivered in partnership with the Department for Science, Innovation and Technology, Innovate UK and the West Midlands Combined Authority.